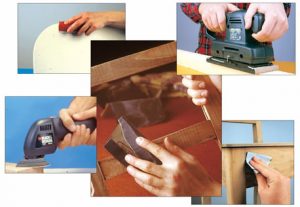

Polishing

Polishing is carried out with sand paper, used to finish wood surfaces which have previously been processed. Sand paper is sold in various grits:

[bullet_list icon=”play” indent=”10px” style=””]

- coarse grit sandpaper is used to smooth the rough edges of wood or eliminated small steps in the joints, which will then need sanding with finer grit paper to remove the scratches left by the previous sanding.

- fine grit sandpaper – used to smooth soft woods and sanding filler

- the very fine-grit sandpaper is used for finishing

[/bullet_list]

In the workshop different grades of paper should be stocked, from 80 to 320, including 100, 120, 150 and 220 as needed for all the various phases of work. Sanding is done by wrapping the sand paper around a soft wood or cork block of various shapes, the block must be used following the grain as using it transversely can leave scratches. Sanding the shellac, however, is done with very fine steel wool type “0000”, with little abrasive power to avoid leaving scratches on this type of finish which is very delicate. Important: if the wood is to be coloured with stained water it is advisable to moisten it before sanding. With a sponge dampened with water, moisten the wood, wait for it to dry and then sand. Water-based paints tend to swell the fibres, creating problems during finishing, with this technique you can limit this inconvenience.